OEM Equipment Parts: Maximizing Performance and Lessening Downtime

OEM Equipment Parts: Maximizing Performance and Lessening Downtime

Blog Article

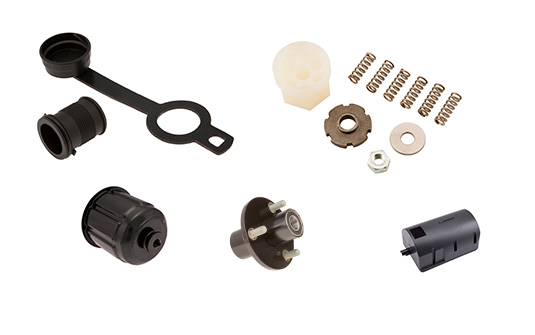

The Benefits and Disadvantages of Choosing OEM Building Parts Over New Parts for Your Tools

When it comes to maintaining and fixing equipment, the choice in between deciding for original devices supplier (OEM) building components versus new parts is an important consideration for numerous companies. While OEM components are designed to fulfill the details demands of the equipment and are frequently linked with a higher degree of top quality and compatibility, there are also downsides to be weighed, such as potential price effects and schedule concerns.

Quality and Compatibility Conveniences

When considering the high quality and compatibility advantages of OEM building and construction parts versus repairs, it is necessary to assess their accuracy engineering and seamless assimilation abilities (OEM Equipment Parts). OEM building components, being initial devices made by the exact same business that created the tools itself, are created to precise specs. This accuracy engineering makes sure that OEM parts are customized to fit seamlessly within the existing equipment, lessening the threat of malfunctions or compatibility concerns. The compatibility benefits of OEM parts prolong past simply fitment, as they are also engineered to work sympathetically with various other parts, optimizing the general performance and durability of the equipment.

In comparison, brand-new components might not use the very same degree of precision design and compatibility as OEM parts. While new components might be a lot more cost-efficient and conveniently offered in some cases, they frequently do not have the meticulous design and quality assurance that come with OEM building parts.

Greater Cost Factors To Consider

Offered the superior top quality and compatibility benefits of OEM building parts over new components, it is crucial to now address the aspect of greater expense considerations in the decision-making process. While OEM components are understood for their precise fit and high performance, they typically come with a higher rate factor contrasted to aftermarket options. The initial investment in OEM components may appear a lot more pricey, however in the lengthy run, they can show to be a lot more cost-efficient due to their toughness and dependability.

One vital aspect to take into consideration when reviewing the higher price of OEM construction components is the prospective financial savings in regards to decreased upkeep and repair costs. OEM parts are crafted to satisfy the details needs of the equipment, which can cause fewer breakdowns and much less downtime. This can equate right into significant cost financial savings for equipment owners in terms of lower repair and replacement expenses over the lifespan of the machinery.

In addition, buying OEM components can also add to keeping the resale value of the tools. Customers frequently like machinery that has been fitted with authentic OEM components, as they are regarded to offer far better quality and performance. This can result in a higher resale value for the devices, countering the preliminary higher cost of OEM parts. Ultimately, while the higher expense of OEM construction components might need a bigger upfront investment, the lasting advantages in terms of cost, reliability, and performance savings make them a feasible and beneficial selection for equipment owners wanting to maximize the value of their investments.

Dependability and Service Warranty Insurance Coverage

In evaluating the selection in between OEM building components and repairs, a critical facet to consider is the level of dependability and warranty coverage offered. OEM building parts, being made by the initial devices manufacturer, are designed to meet the exact specs of the tools, making certain a high level of dependability. These parts go through strenuous screening to ensure compatibility and resilience, reducing the risk of breakdowns my website and malfunctions. Additionally, OEM components commonly include a guarantee that supplies insurance coverage for a specified period, providing satisfaction to devices owners in instance of unexpected concerns.

On the other hand, new parts might not always provide the exact same degree of dependability as OEM parts, as they might not have actually been especially made for the tools in inquiry. When taking into consideration integrity and guarantee protection, deciding for OEM building and construction parts might supply an extra safe and secure and dependable solution for equipment maintenance and long life.

Efficiency and Longevity Enhancements

Having actually developed the importance of reliability and warranty protection in the choice between OEM building and construction components and brand-new parts, the focus currently changes in the direction of assessing exactly how these elements add to efficiency and durability enhancements. OEM construction visit here components are crafted to specific specifications, guaranteeing smooth assimilation and optimum performance within the equipment. This accuracy leads to boosted overall effectiveness and productivity, as the parts are developed to work sympathetically with the machinery they are meant for.

Moreover, OEM components typically undertake extensive testing to meet market standards and producer demands, ensuring a higher level of high quality contrasted to common alternatives. This remarkable top quality translates right into raised sturdiness and long life for the equipment, decreasing the risk of unanticipated failures and pricey repair services. By utilizing OEM building parts, equipment owners can experience better performance, prolonged life expectancy, and decreased downtime, inevitably causing boosted functional efficiency and cost-effectiveness in the future.

Potential Minimal Schedule Issues

When counting on OEM building and construction components for devices repair and maintenance, one considerable downside that can occur is the prospective restricted accessibility of these parts. As a result of aspects such as production routines, supply chain disturbances, or the discontinuation of particular components by producers, there may be instances where OEM parts come to be scarce and even obsolete. This shortage can bring about delays in devices servicing, extended downtime, and boosted expenses linked with sourcing different solutions.

Limited availability of blog here OEM construction parts can also hamper the efficiency of maintenance groups, as they might need to invest added time and effort browsing for ideal replacements or awaiting back-ordered components to show up. In cases where particular OEM components are essential for optimal equipment performance or safety and security conformity, the unavailability of these components can pose significant functional dangers. To alleviate these difficulties, equipment managers should maintain clear interaction with distributors, check out options for equipping essential parts beforehand, and take into consideration alternate remedies or aftermarket components when OEM choices are limited.

Verdict

In verdict, when thinking about whether to pick OEM construction components over repairs for tools, it is very important to weigh the benefits of high quality, compatibility, integrity, efficiency, and long life against the disadvantages of greater expense and potential minimal accessibility. Inevitably, the decision should be based on the specific needs and top priorities of the tools owner, in addition to the significance of warranty protection in making sure long-lasting complete satisfaction and functional efficiency.

When it comes to keeping and repairing devices, the decision in between deciding for original tools producer (OEM) building and construction parts versus brand-new parts is an essential factor to consider for several organizations.Offered the remarkable top quality and compatibility advantages of OEM construction parts over brand-new parts, it is crucial to now resolve the facet of greater cost considerations in the decision-making process. OEM Equipment Parts.On the various other hand, brand-new components may not always offer the same degree of dependability as OEM components, as they might not have actually been specifically developed for the tools in inquiry.When relying on OEM building and construction parts for equipment maintenance and repairs, one substantial downside that can emerge is the possible limited accessibility of these parts. To alleviate these difficulties, devices managers ought to preserve clear interaction with suppliers, check out choices for equipping important parts in development, and consider alternative services or aftermarket components when OEM alternatives are limited

Report this page